Inlet Temperature F. PROCESS DESIGN OF AIR COOLED HEAT EXCHANGERS AIR COOLERS ORIGINAL EDITION.

Pdf Optimization Of Air Cooled Heat Exchanger Design Using Htri Research And Scientific Innovation Society Rsis International Academia Edu

Progress in forced-air heat exchanger technology is hampered by the fundamental physical.

. To vaporize a liquid stream. Use caution in applying excessive service factors or allow-ing excessive drive load capacity. Calculations of Heat Exchanger 3.

Air cooling is limited by specific heat. 60 Heat Transfer 70 Dry Bulb Temperature 80 Psychrometrics Concepts 90 Basic Air Conditioning Calculations 100 Heat Loss by Conduction 110 Overall Coefficient of Heat Transmission U 120 Heat Loss Calculations 130 Heat Conduction and Thermal Resistance 140 - Heat Loss due Air Change ACH and. Either Design Flex software or the formulas published in the appropriate Drive Design Manual can be used to calculate the standard recommended level of belt installation tension.

AIR COOLED FIN FAN HEAT EXCHANGER SELECTION SIZING AND TROUBLESHOOTING Kolmetz Handbook Of Process Equipment Design March 2020 Project. Brian R Lamb in Plant Engineers Handbook 2001. Our heat exchangers help your system work smarter.

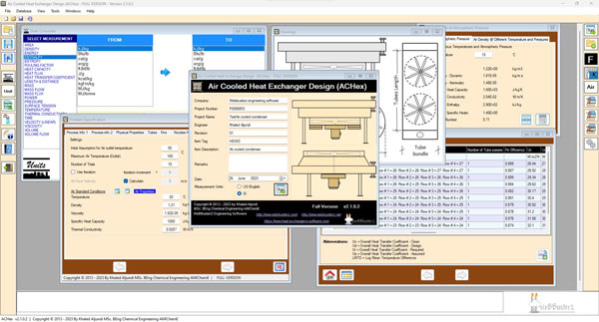

Air Cooled Heat Exchanger This web application does preliminary estimation of Finned Area Face Area Total Fan Power Air Outlet Temperature for an Air Cooler. The example shown in Figure 6 is an actual air-cooled heat exchanger installation with 0718 wg static pressure and 126738 cubic feet per minute. 1air cooled heat exchanger.

Learn how from the experts at SRC. Since the air-cooled heat exchanger is exposed to changing climatic conditions problems of control of the air cooler become relevant. Double-pipe heat exchanger a When the other fluid flows into the annular gap between two tubes one fluid flows through the smaller pipe.

Ad Designed and engineered for quality. In heat exchanger design there is a trade off between the cost of the heat exchanger which is a function of the heat transfer area and of the type of construction and the cost of the heating and cooling media. The Basic Design Equation and Overall Heat Transfer Coefficient The basic heat exchanger equations applicable to shell and tube exchangers were developed in Chapter 1.

Air-cooled heat transfer equipment offers a satisfactory solution. T1 T2 T1 T2 x The Simplest Heat Exchanger. To heat or cool a stream flowering from equipment to another.

Access Free Process Design Of Air Cooled Heat Exchangers Air Coolers Completely revised and updated to reflect current advances in heat exchanger technology Heat Exchanger Design Handbook Second Edition includes enhanced figures and thermal effectiveness charts tables new chapter and additional topics--all while keeping the qualities that made the. Because of natural convection an air cooled exchanger will continue to dissipate heat albeit at lower than design rate even without the fans running. T 1 air inlet temperature c T 2 air outlet temperature c w flowrate of the fluid to cool lbh c specific heat of the fluid to cool.

Heat transfer enhancement techniques and novel design concepts allow Increase in performance for fixed size andor Weight or conversely Reduction in heat exchanger size andor weight Reduction in size and weight are not the same HX layout in a typical Aircraft Air Conditioning ACS Pack Schematic of a typical single-pass cross-flow. 01 April 2011 At least two fans shall be provided for each bay. Higher flow speed larger noise.

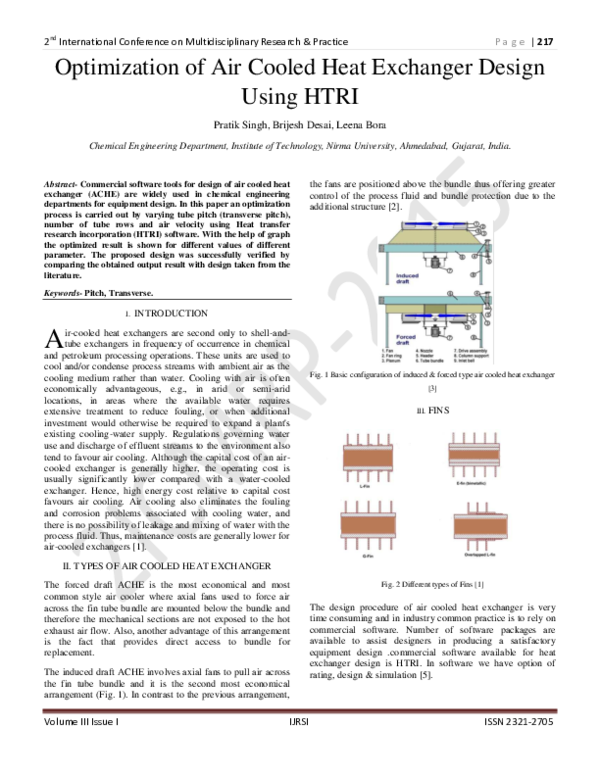

An ACHE is a device for rejecting heat from a fluid directly to ambient airThis is in contrast to rejecting heat to water and then rejecting it to air as with a shell and tube heat exchanger and a wet cooling tower system. Therefore our design calculation will be based on 4 C. DT m 4 C A Q U DT m 1170 9454 0309523 m2 309523 cm2 Case I- Number of Tubes N t 7.

The most common problems in heat exchanger design are rating and sizing. Browse SRC industrial heat exchanger products. This standard specification is reviewed and updated by the relevant technical committee on Sep.

A decision must be made as to what the. The obvious advantage of an ACHE is that it does not require water which means that plants requiring large. Laminar flowMost plate heat exchanger designs.

Heat Transfer Applications 4. Any deviation from this requirement will need the prior approval of the Company. The temperature difference between the fluid and the wall varies along the length of the heat exchanger.

HUDSON PRODUCTS CORPORATION The Design of Quiet Air-Cooled Heat Exchangers Page 1 of 20 The Design of Quiet Air-Cooled Heat Exchangers A Paper for The Energy Resources Conservation Board. From dust pollen etc 3 high electrical power consumption related to fan aerodynamic efficiency and 4 heat exchanger cooling capacity limitations i mposed by fan noise. Heat transfer coefficients for air an liquid flows are orders of.

2 performance degradation due to heat exchanger fouling eg. The design of an air-cooled heat exchanger. Design and calculation of air-cooled heat exchanger.

Liquid cooling is able to achieve better heat transfer at much lower mass flow rates. To dissipate large amounts of power a large mass flow rate is needed. Verify if the calculated heat exchanger is sufficient.

Freezers air heaters cookers ovens and so on. Fans in Various Duties Where for reasons of control an air-cooled heat exchanger. PROCESS DESIGN OF AIR COOLED HEAT EXCHANGERS AIR COOLERS PROJECT STANDARDS AND SPECIFICATIONS Page 5 of 19 Rev.

2 The air-cooled condenser The air-cooled condenser is a steam-air heat exchanger composed by several modules such as that sketched by fig. Lower flow speed lower noise. The purpose of the heat exchanger is.

The primary objective in the thermal design. An air conditioning project needs to cool 333kgs of air from dry bulb temperature t 1 23 relative humidity ψ 1 60 to dry bulb temperature t 2 12 relative humidity ψ 2 90 and the condenser outlet is For saturated liquid at 40 R22 is used as the refrigerant. Here we will cite only those that are immediately useful for design in shell and tube heat exchangers with sensible heat transfer on the shell-side.

Construction of Shell-And-Tube Heat Exchangers. Rated belt drive capacity should not exceed about 3X the design load. Account the design and operating data of a condenser installed in a 400 MW combined cycle power plant still operative in the Italian electricity market.

However there are more parameters to be considered in the design of an air-cooled exchanger. DoublePipe Heat exchanger counter current cold less cold less hot hot. Kolmetz Handbook of Process Equipment Design.

The rating problem is concerned with the determination of the heat transfer rate. T 1 inlet temperature of the fluid to cool c t 2 outlet temperature of the fluid to cool c 8. Lectures 19 Applied Heat Transfer CM3110 1232019 3 T outer bulk temperature T inner bulk temperature L BUT.

Induced draught units perform better than do forced draught units in this respect as the plenum chamber and.

Pdf Acc Design Calculation Sudhir Bisen Academia Edu

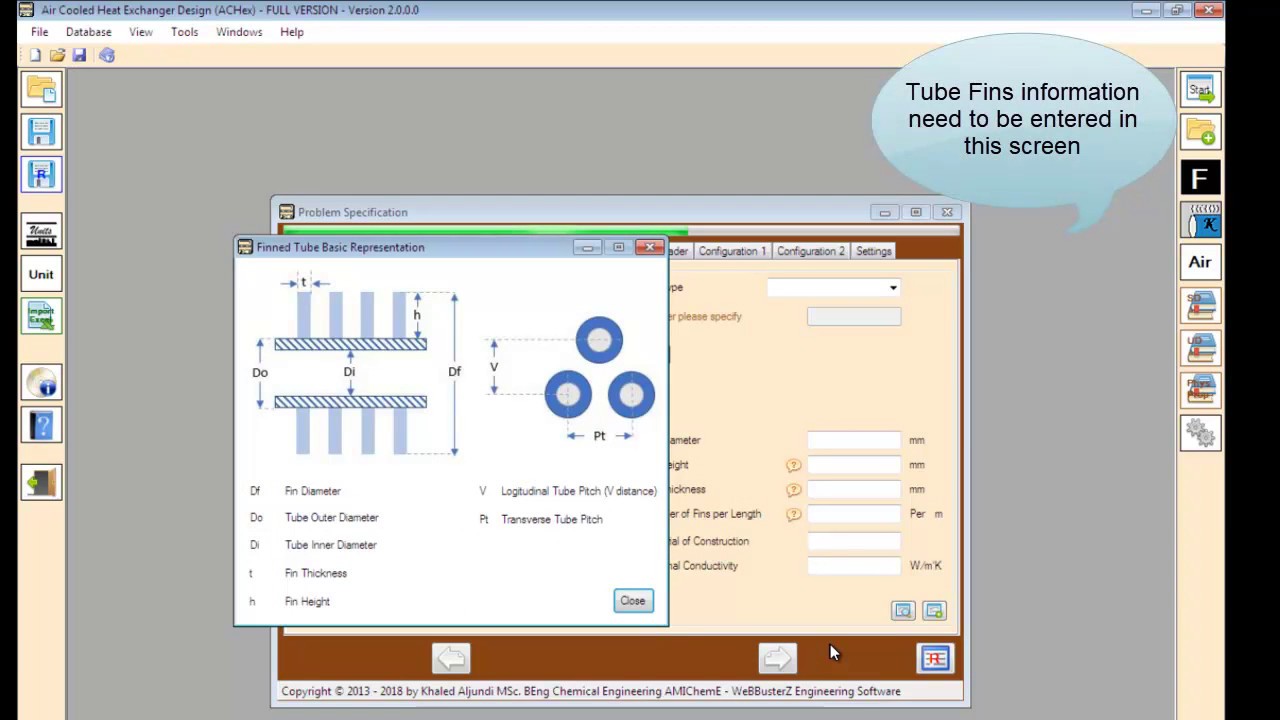

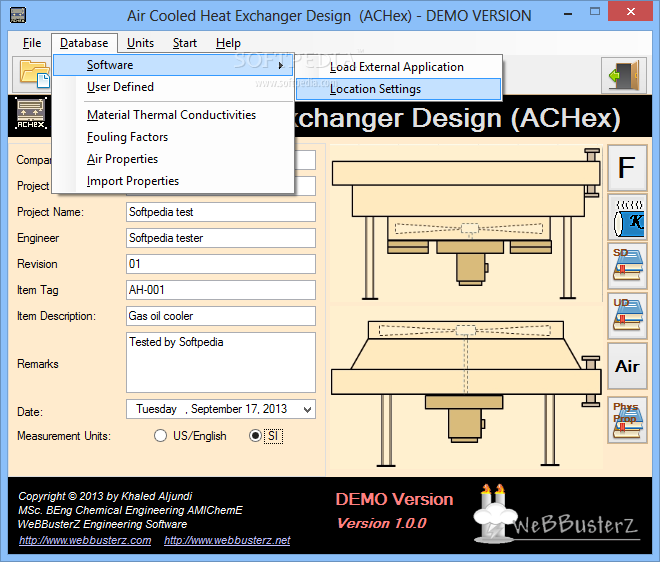

Air Cooled Heat Exchanger Design 2 0 0 1 Free Download

Download Air Cooled Heat Exchanger Design 1 0 0 0

Pdf Air Cooled Fin Fan Heat Exchanger Selection Sizing And Troubleshooting Kolmetz Handbook Of Process Equipment Design

Pdf Air Cooled Heat Exchanger Design Gerard Hawkins Academia Edu

Air Cooled Heat Exchanger Design 2 0 0 1 Free Download

Air Cooled Heat Exchanger Design Step By Step Calculation Guide

0 komentar

Posting Komentar